| Home | Designs | Testing | Mobilize |

Pattern & Instructions for High-Quality Cloth Mask

On April 2, 2020 the US CDC finally recommended the use of face masks for the general population, partially recognizing what public health experts have known all along. Lacking broad herd immunity or innoculation the only measures slowing the spread of Covid-19 are human actions - distancing, washing, and stopping the exchange of respiratory droplets carrying the virus. (The 461,432 confirmed US caseson April 10, 2020 represent only 0.14% of the population, so even if the actual infection rate is an order of magnitude larger almost all the population are potential hosts.) The CDC provides DIY guidance, but continues to discourage the use of surgical masks and N-95 respirators, seeking to reserve dwindling supplies for health and medical personnel. As anticipated by community health providers this devil’s choice of protecting yourself and those around you versus protecting those in health professions has become irrelevant. The national stockpile is essentially depleted, demand vastly outstrips production and continues to grow, and supply chains of traditional commercial masks remain seriously compromised. Health professionals are going to need alternatives to turn to this week, regardless.

We must take a different national approach. Manufacture massive quantities of masks and other PPE that provide strong protection through channels available in communities everywhere using locally available materials and develop operational protocols for safe re-use. Protect the population and those who care for us.

No occupation should be without masks. Every step of the food chain, those harvesting the fields, shipping to stores, in the grocery store, cooking or serving - all should be protected and protecting others. No marketing concern - “people will fear that X is not safe if our workers wear masks” - is worth dying for.

This approach means the use of fabric and filter materials that are widely available throughout the economy, rather than relying on the specialized materials and mechanisms narrowly provided for traditional suppliers. It means the use of manufacturing methods that are indemic in our communities - sewing. It means using local production for immediate delivery. These enable rapid ramp to scale directly to the faces that need the PPE.

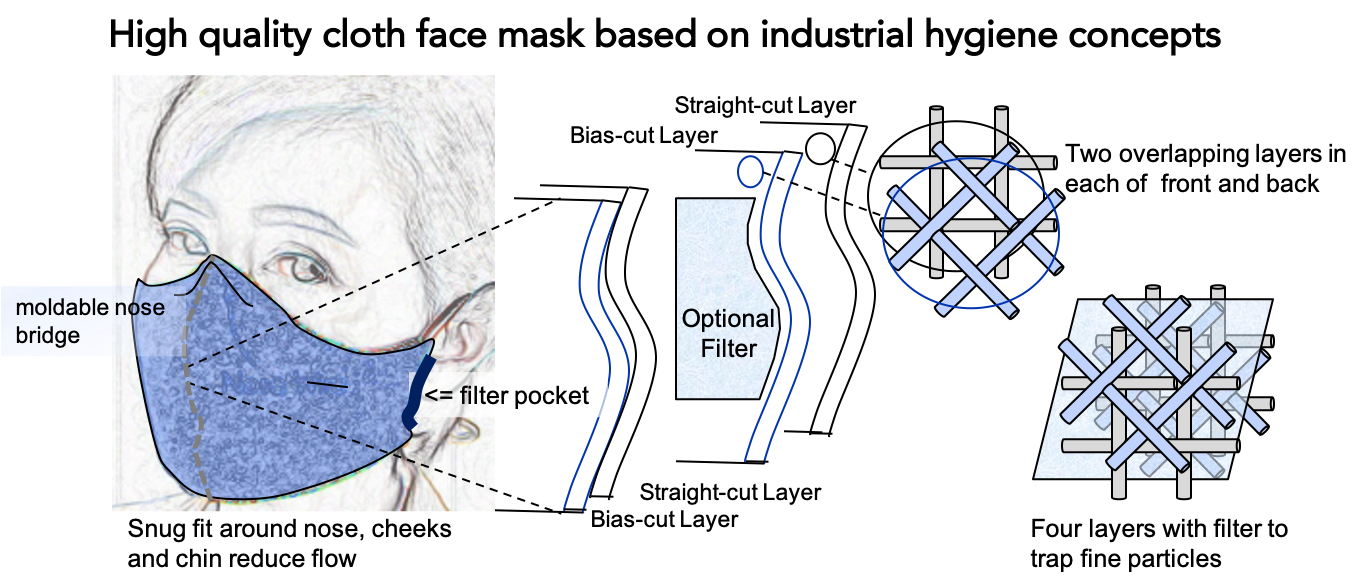

Many good designs have been developed and put into production in some manner, from DIY to fashion. One developed at Project PPE 4 Central Coast in conjunction with the Monterey and Santa Cruz Medicial Societies is described here. The mask consists of front and back parts forming an interstitial pocket that can hold an optional filter - HEPA vacuum bag, coffee filter, anti-static face mask material, whatever. Each of the parts are formed of two 100% cotton layers of reasonably high thread count. One layer is straight cut (with the grain of the fabric) and one bias cut (on a 45 degree) so that the varying overlap can reduce porocity and increase interception. The pattern, modeled on the traditional N-95, provides a snug fit around the nose, along the cheeks, and under the chin to reduce escape. A simple modable wire is sewn in to the front layer to form the nose bridge. Washing in soapy water for repeated use.

For many individuals, a simpler 2-Layer mask may be a more approachable alternative. It is easier to sew and requires less material. These simpler designs may also be the right choice for low-risk settings, as they can be produced cheaper and faster.

These designs provide a DIY avenue for individuals and community groups to protect themselves, but also provide ways to mobilize production resources in the community. The can potentially be produced by essentially any company working with textiles - apparel manufacturers, backpacks, outdoor gear, sail makers, sewing contractors, etc.

Designs

Here is links to some of the better designs out there. NY Times Overview

Simpler variant of the 4-layer IFL mask below, and 2-layer option

4 layer with pocket, N-95 form factor by Monterey / Santa Cruz Medical Soc., Idea Fab Lab, ppe4cc.org, pattern

2 layer, pleated, with ties by Kaiser Permanente

2 layer, pleated, with ties, St Joseph Hospital

2 layer with ear loops by Emory Health

2 layer with nose bridge, seam down front, single tie head strap

GetUsPPE recognized face mask projects

Testing - determining performance and efficacy

Often described as “qualitative seal testing” the NIOSH provides a [good descritption of how to put on and take off a mask] (https://www.cdc.gov/niosh/docs/2010-133/pdfs/2010-133.pdf). Except for the “dispose” part, it is common sense for washable masks too.

There are big questions around how effective are these and various other measures. A good discussion of these issues is available from the CDC around the 2009 H1N1 influenza outbreak. Part of the challenge is that filtering the intake of particulate matter is not entirely the same issue as preventing the transfer of small viral entities in respiratory water droplets. Some of comments in the CDC blog observe that absorbing and retaining moisture is an important factor. And it is not just a matter of filter, it is also a question of fit and how people actually use them.

The filter ratings basically reflect what percentage of particles 0.3 microns or larger are removed, N-95 for 95%. Some observe that the virus is smaller than this. But, this neglects that it is not floating in isolation, but carried on droplets of excretions. Here’s filter FAQs.

The NIOSH provides a nice video in how N-95 tests are performed. Basically, masks are fixed with wax over a hole in a metal plate and the fraction of airborn salt particles that pass from front to back are measured. Watching this raises many questions. It says nothing about effectiveness of fit or use. But, moreover, it is only establishing a rating for inward flow - protection of the wearer. This is appropriate for many of the uses of respiratory masks. But not for protecting others from possible infection of the wearer. Particularly concerning is the exhalation valve in the classic 3M™ 8511 N95 Particulate Respirator. What keeps viral droplets from escaping with exhaled breadth? Nothing in the NIOSH test addresses this. It is not clear that we know more about the use of conventional masks than we do about cloth ones.

The National Personal Protective Technology Laboratory (NPPTL) provides additional material, including some filtering out the confusion white papers at https://knowits.niosh.gov that are supposed to help answer our questions. It answers some.

We are starting to see some studies of design options and trade-offs. Those will be essential. Some recent preliminary data seems to indicate a three-fold increase in filtration efficiency going from 2 to 4 layers of 600 threadcount cotton, a large improvement over 400 thread count, and marginal additional benefit of 1000 thread count. Seems that little attention has been paid to cotton batting options.

Cambridge 2013 study of homemade facemasks in Influenza Pandemic

https://jennifermaker.com/diy-face-mask-filter-materials/

Mobilizing

Ultimately, the questions we all need to be asking is how are our local health providers going to get through these coming weeks and what it going to be the plan as the restrictions which are so essential in hammering down the spread begin to be lifted. What is our county’s public health plan.

There are nearly 5,000 GoFundMe efforts for PPE. There are many efforts, such as https://getusppe.org/, to engage the Maker community. Designs can be submitted for analysis. Also many matchmaking efforts, https://www.donateppe.org/, https://www.mask-match.com/.

But communities need to go into local production now. Some are utilizing recently unemployed individuals with sewing skills, providing kits of cut patterns to accelerate production. Others are engaging local manufacturers with textile capacity to produce in volume. We could imagine every neighborhood working with their local “dry cleaning and alternations” firm to generate masks and much needed income. Retirement communities are discovering that the very people who are so vulnerable and needs masks dearly have the sewing skills to make them. There does not yet seem to be a clearing house of guidance for how to translate community desire to help into physical resources that will be put to use in the challenging days ahead. That is a much more subtle, politically complicated process than actually making masks, but it fundamentally depends on them getting made and distributed.

At the industrial scale, FEMA airbridge has some elements.